מוצרים

5-axis milling machine

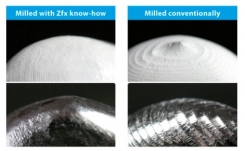

Up to triple productivity with Zfx milling strategies compared to conventional systems.

Manufacturing units, which are capable of implementing even highly complex geometries by means of 5-axis simultaneous machining, are used in Zfx milling centers. Both available machines have been carefully tested over many years and have been optimally incorporated into Zfx‘s digital workflow.

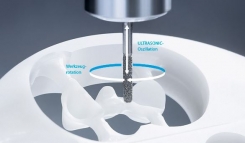

SAUER – ULTRASONIC 20 linear

The SAUER – ULTRASONIC 20 linear milling machine is based on a special actuator system, by means of which an ultrasonic frequency is transmitted from the spindle to the tool holding fixture by means of induction.

This generates an additional oscillating kinetic movement in the tool, resulting in a considerable reduction of the effective process forces, a significant increase in the chip removal rate and the best surface quality for the dental prosthesis.

Zfx Ultramill

The Zfx Ultramill machining center impresses with its rigidity and low vibration characteristics, which lead to high dynamic performance and manufacturing precision. Among other things, this is made possible by the reinforced concrete structure on which the machine bed and travelling columns are based.

Highlights ULTRASONIC 20 linear:

5-axis ULTRASONIC & HSC milling on a single machine

Compact, thermo-symmetric gantry construction in monoBLOCK design

Materials ranging from PMMA and cobalt-chromium to sintered zirconium oxide on a single machine

Highest dynamic performance via linear technology > 2 g

Component precision in the ìm range

NC swivel rotary table for 5-axis simultaneous machining (undercuts)

Water-cooled spindle with max. 42,000 rpm

Siemens 840 D solutionline control system with 19" TFT display and special ULTRASONIC software features: ADC and ACC

compact design – 3,5 m2 floor space

הוספה לרשימה שלי

הוספה לרשימה שלי