מצא את השתל המתאים לך ביותר

מוצרים

שטח הפנים

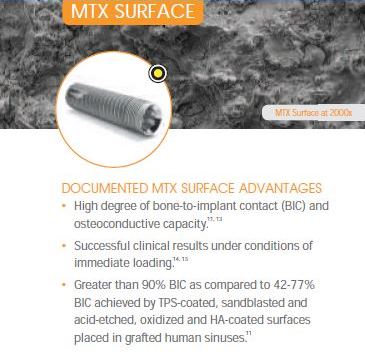

MTX Microtextured Titanium

Zimmer Dental’s MTX surface allows for increased bone apposition for long-term success

MTX is a non-coated, microtextured surface created by grit-blasting the machined titanium implant surface with hydroxylapatite (HA) particles, followed by washing in non-etching acid and distilled water baths to remove residual blasting material.

The MTX process does not weaken the titanium implant body, ensuring that the strength of the implant is maintained. Furthermore, implant threads are not rounded by the MTX process, and cutting grooves remain intact for efficient self-tapping.

While all microtextured titanium surfaces share some of the same roughness parameters, great variations in peaks and valleys can occur, depending on the surface treatment.1-2 MTX treatment results in a relatively uniform surface of closely spaced micropits that have demonstrated excellent results at both the histomorphometric1 and clinical levels.1-4

Histomorphometric Evaluations

The MTX surface has been shown to allow for increased bone apposition compared to machined surfaces. In a clinical study involving the placement of experimental microimplants with split machined and MTX surface topographies into grafted and non-grafted human sinuses, mean bone-to-implant contact was significantly greater for MTX (72.31% ± 17.76%) compared to the machined surfaces (38.01% ± 19.32%).3

In a recent study4, the MTX surface achieved excellent bone-to-implant contact and osteoconductive capacity.

References

1Mazor Z, Cohen DK. Preliminary 3-dimensional surface roughness measurement and early loading results with a microtextured implant surface. Int J Oral Maxillofac Implants 2003;18(5):729-738.

2Al-Nawas B, Götz H. Three-dimensional topographic and metrologic evaluation of dental implants by confocal laser scanning microscopy. Clin Implant Dent Relat Res 2003;5(3):176-183.

3Trisi P, Marcato C, Todisco M. Bone-to-implant apposition with machined and MTX microtextured implant surfaces in human sinus grafts. Int J Periodontics Restorative Dent 2003;23(5):427-437.

4Todisco M, Trisi P. Histomorphometric evaluation of six dental implant surfaces after early loading in augmented human sinuses. J Oral Implantol 2006;32(4):153-166.

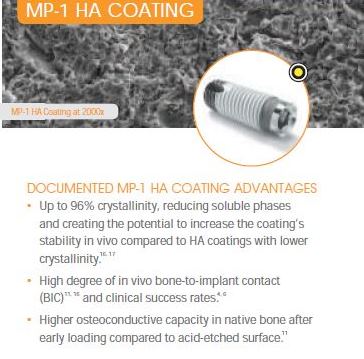

MP-1® HA Coating

Zimmer Dental’s MP-1 HA process increases HA crystalline content for greater coating stability

Through nearly two decades of continuing clinical research, Zimmer Dental has developed its proprietary HA coating process – the MP-1 process. It increases the average crystalline content of the HA from 77%

to >90%, contributing to greater coating stability than lower crystalline HA coatings.1

Clinical Evaluations

HA-coated implant surfaces have been shown in independent studies to be highly effective in achieving and maintaining excellent bone-to-implant contact. In one clinical study, the cumulative 5-year survival rate was 99.3% for almost 4,000 Zimmer Dental Spline® implants with MP-1 HA coating.2 Results may vary.

References

1 Data on file.

2 Pikos MA, Cannizzaro G, Korompilas L, Turrillas EA, El Askary AES, Rao W, Carusi G, Lauverjat YMP. International retrospective multicenter study of 8130 HA-coated cylinder implants: 5-year survival data. International Magazine of Oral Implantology 2002:3(1):6-15.

הוספה לרשימה שלי

הוספה לרשימה שלי